WE’VE MADE LEASING SIMPLE & EASY! CLICK HERE FOR DETAILS.

CNC Machines by Material

Browse our CNC Machines by material being processed

CNT customers are machining just about any material, including Alucobond, curtain wall, vinyl, granite/stone/marble, aluminum, ferrous and non-ferrous metals, foam/plastics, wood, solid surface, ceramic, reinforced fiberglass, honeycomb, and carbon/carbon fiber composites.

The material being fabricated plays a great role in determining which machine best suits your needs. Special tooling, fixturing, bridge designs and table configurations are available for most machining needs. If you don’t see something that meets your specific requirements, contact us and let’s talk about how to take your productivity to the next level.

ACM Panel / Alucobond CNC Machining

Our CNC machines are being used on ACM panels from top manufacturers

CNT Motion was contacted by a Colorado-based fabricator looking to machine Alucobond® Composite Panels for pre-engineered commercial building exterior cladding. The company, which has supplied over 6.5 million square feet of composite panels all over the United States, turned to CNT to provide an automated solution large enough to handle two panels at a time and accurate enough to V-groove to within +0.002″ depth over a 5′ X 24′ surface area. This was the first of this machine style we’ve built for this company and various others.

Wood, Plastics/Composites and Non-Ferrous Metals

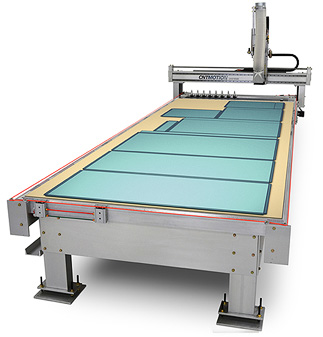

CNT-1000 Series Base Model

The CNT-1000 Series is a full-sized, servo-powered, high-performance machine designed for heavier applications, including nested-based fabrication of plastics, hardwoods, solid surface and non-ferrous metals. Add the optional spindles, vacuum system, dust collection system and tool changer, and you have a first-class production machine ready to handle the most-demanding jobs.

CNT-950 Series Base Model

The servo-powered CNT-950 is our most-affordable model and perfect for those new to CNC technology. It’s also a great second or third machine for manufacturers looking to expand their current production capabilities. The CNT-950 is built to the same precision standards as all of our machines and is our most-flexible model — we can build it with virtually any table size. It’s also another great machine for nested-based manufacturing, so you can get the most out of your material.

Four Heads Cutting Simultaneously

This machine was one of four routers shipped to China for a CNT Motion customer who was setting up a new production facility for manufacturing snow boards and skis. The company, which bought two of these unique four-headed machines, came to us through their supplier of wood cores (also a CNT Motion customer). By producing four to eight boards at the same time, with a cycle time only minutes long, the company is producing hundreds of thousands of products a year. And, during their peak season, they’re running the machines 24/7!

Four Heads with Front-Loading Table

A renowned manufacturer of inspirational art, home decor and gifts has deployed two identical four-headed machines for 3D high-resolution (4000 steps per inch/.0002) carving of various hardwoods — four to eight pieces at a time. To ease material loading/unloading, CNT Motion specially designed a custom 12’X4′ front-loading table.

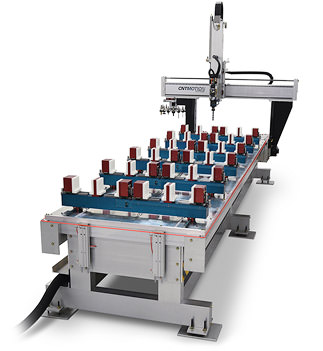

Extrusions Machining

12-foot-long Table for Extrusions

Since 1999, CNT has designed and built machines engineered to drill and mill aluminum extrusions for a variety of applications (including door & window frames, aircraft components, lighting enclosures and wall systems) and machine small parts for high production. With a 12-foot bed, 24 vise clamp positions, eight pop-up position stops, pivoting head, 15-position automatic tool changer and alcohol coolant system, this CNT-1000 provides a single-step automated solution. On the machine pictured here, the vise deck is removable to allow access to a fully functional vacuum grid bed for machining aluminum sheet material. The vise deck is removed using four lifting rings and easily and accurately reinstalled using location pins.

CNC Routers/Mills for Machining Extrusions and Bar Stock

CNT Motion has been producing large-work-area metalworking CNC Router/Mills as a cost-effective solution for milling large, light-gauge to medium-thickness steel, aluminum, copper, brass and other metal bar/plate. Many of our customers have found that our CNC Router/Mills are ideally suited for their specific applications, providing greater flexibility, higher speeds and larger work areas than traditional vertical machining centers.

Foam and Expanded Polystyrene Shaping

CNT-950 Surfboard Shaping Machine

Since 2000, CNT has been building machines for high-production surfboard and stand-up paddleboard (SUP) shaping. Incorporating a specialized support system, digitizing capability and industry-standard shaping software, this machine has enabled our clients to successfully pursue this challenging market using automation to boost both productivity and creativity.

Ceramics, Fiber-Reinforced Composite (FRC)

Profiling, Grooving and Polishing

In 1997, CNT Motion designed and built the first of five machines for a customer specializing in the management of water removal and sheet formation on all types of pulp and paper machines. Their unique process combines heat and air flow to remove moisture content from pulp. Currently, they have five CNT machines (three in the U.S. and two in the APAC region) used for profiling fiber-reinforced plastic 2″ tall, 4″ wide and up to 35′ in length. Once machined, 2″ ceramic profiles are bonded to the material and (using the same machine) ground to within .002″ tolerance over the entire length and then polished to a #5-8 finish.

Aluminum, Fiberglass Poles

Aluminum, Fiberglass Pole Lathe/Mill with Live Tooling

This unique machine design best illustrates CNT Motion’s ability to provide automation solutions to boost throughput and create a fully autonomous state-of-the-art composite fabrication facility. This machine was the centerpiece of a design that incorporated a CNC extractor feeding a CNC overhead auto-loader/unloader with part orientation and size identification, then feeding this lathe/mill unit, back to unloader and then, finally, to an out-feed conveyor.

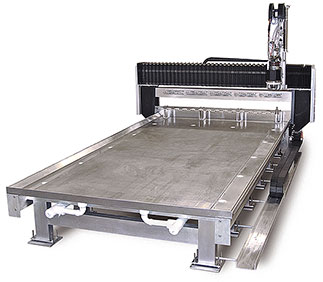

Granite, Stone and Concrete Fabrication

CNT-1000 Granite and Stone Profiling, Grinding and Polishing Machine

A Virginia-based state-of-the-art facility has deployed two of these powerful CNT machines for high-precision stone counter top and mantle fabrication. This machine holds 30 tools (15 on-the-fly; 15 rack-mounted) and has a 72”X168” cutting area.

We stand behind every machine we build.

And we back them up with a warranty that ensures quality and dependability.

MATERIAL QUESTIONS?

CNT Motion Systems has the answers.

If you’re not sure which machine is best-suited for the material you’re processing, drop us a line and we’ll offer some advice.