Enginneered for Durability

Industrial-Quality Reliable Components

At CNT Motion Systems, we know that purchasing a CNC machine is one of the most important business decisions you’ll ever make. We engineer all of our products for performance, flexibility and affordability and believe that they are only as good as the quality of the components we put into them.

We use components with many years of proven success. Our component selection is driven by quality, not price, bringing consistency with no surprises. From our standard equipment, like high-load-carrying durable Hiwin bearings, to our optional tool changers and vacuum system, we provide what you need to consistently get the most out of your machine. As your manufacturing needs continue to grow, you can rest assured knowing that your machine will perform efficiently and reliably for years to come.

Control it from a PC!

Every CNC machine comes with WinCNC Software pre-installed. Ask about our industry-specific custom applications.

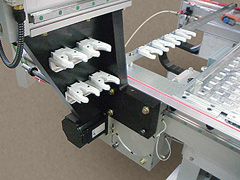

Tool Changing System

CNT Motion offers tool changers for all of our standard and custom machines. The system features a 10-HP HSD, Mach Swiss, Perske or Elte ISO-30 or HSK-F63 tool changer, available in one-tool increments. Each tool changer also features ISO-30 cones with either ER32 collets (for up to 3/4″ bits) or ER40 collets (for up to 1″ bits).

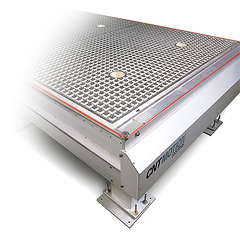

Vacuum System with Blower

CNT Motion’s vacuum system features a plenum grid made of aluminum-cast tool and jig plate. Aluminum is the material of choice of all manufacturers of heavy-duty machines due to its greater stability than plastics or composites. Two available blower styles are geared toward specific applications: a 25-HP FPZ regenerative blower; or a 7.5-HP claw pump.

HIWIN Ball Screws

HIWIN precision ball screws provide smooth and accurate vertical Z-axis movement, together with low drive torque, high stiffness and quiet motion. Other benefits include high efficiency, reversibility, backlash elimination and high lead accuracy.

Pressurized and Lubricated 25mm Bearing System

Using recirculating balls between the rail and the block, the four-row guideway achieves high-precision linear motion that can withstand substantial loading in perpendicular and traverse axes. These bearings also have less friction than other linear guideway systems and satisfy all the requirements of any highly accurate linear guidance system. Shown with CNT’s built-in, pressurized air and lubrication system.

Micro-Misting/Coolant Systems

For non-ferrous metal fabrication, CNT offers three different misting systems to keep your tooling and material from over-heating. We’ll help you choose the best system to suit your needs.

Vegetable-oil-based Misting System

- Best for light-duty applications and most-economical

- Uses minimal amount of oil to minimize spoil board contamination

- Small reservoir and leaves trace amount of oil on part.

SMC Water-based Misting System

- Best for deep drilling and milling

- Available with small or large reservoirs

- Controls amount of fluid and air on part

- Best used with a vise or mechanical hold-down

SMC Denatured Alcohol-based Misting System

- Best for sheet and extrusion work

- Leaves part cold and dry

- No contamination of spoil board

- Available with small or large reservoirs

- Use with any hold-down system

Coolant System

- Best for heavy-duty machining

- Controls amount of fluid used

- Requires a holding tank

- Best when used with a vise or mechanical hold-down

Optional Tabletop Lathe for CNT-1000 & CNT-950

CNT’s add-on lathe unit provides the versatility to turn intricate lathe work on your CNC Router without sacrificing the existing work envelope. The lathe option is available in a variety of sizes based on table length, width and bridge clearance. When purchased with a new machine order, they are designed to align by matching precision pins on the bottom of the lathe to corresponding holes in the vacuum grid. For existing machines, a program is provided that will machine these location holes in your vacuum grid for fast and accurate location and mounting.

CNT’s Optional Tabletop Lathe Features:

- Lathe C-axis;

- Customer-specified orientation: limited by table length, width and bridge clearance;

- Nabtesco 53.5:1 gear ratio;

- 30 RPM (maximum) spindle rotation C-axis;

- Three jaw chucks for custom dog or part-holding fixture;

- Tail stock on plate slide;

- Danaher servo motor and drive and all cables;

- Locating pins for easy removal and installation to vacuum table surface.

32-mm Head

Allows you to drill 1-15 holes simultaneously, making your CNC machine compatible with 32-mm applications. However, some 32-mm applications require point-to-point machines to perform end boring, which requires a special head assembly and fixturing. This system is not suited for nested-based manufacturing.

Spindles, Routers and Saws

CNT Motion offers a variety of accessories are available for numerous CNC machining applications. (Contact us for a complete listing of available accessories.)

Computer Controller Cabinet

Every CNC machining center that we sell is delivered with an PC-based controller. This durable, steel, NEMA 12-rated, pressurized cabinet houses both the PC and the electronics for your machine and is the best way to keep your equipment protected from your workshop environment.

BUT WAIT, THERE’S MORE!

It’s all backed-up with a commitment to top-notch customer service.

We build our CNC machines with rugged components and back them up with stellar service and support. We’re your partner in production every step of the way.