Solid Surface CNC Routers

Improve Efficiency and Reduce Material Waste!

Solid Surface CNC Solutions from CNT Motion

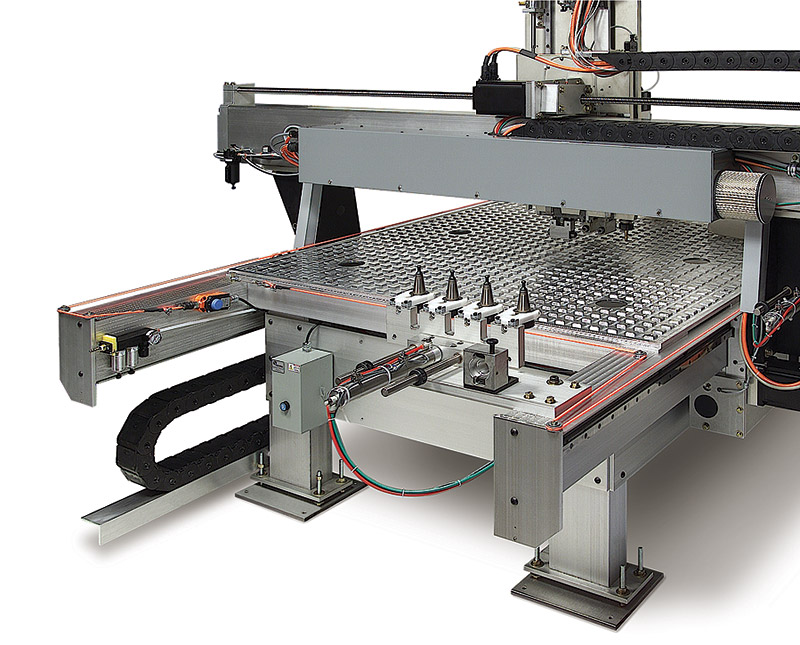

The CNT-950 Series Solid Surface CNC Model and 1000 Series Base Model routers are solid solutions for solid surface fabrication. Equipped with standard 5’ X 12’ cutting areas, they can be expanded for unique applications. With a CNT Motion CNC router, you’ll greatly expand your capabilities, improve efficiency and reduce material waste, all while maintaining accuracy and consistency across multiple parts production. Great for kitchen countertops, bathroom vanities, tub surrounds and more, residential and commercial. Featuring automatic tool changers, pop-up location pins, powerful vacuum fixturing and more, we engineer all of our products for performance, flexibility and affordability.

Not sure which machine is the right choice? Let’s talk. We’ll even help you determine which tooling best suits your needs.

*Due to fluctuating supply markets, prices shown are subject to change. Please use pricing shown for reference only. Machines will be quoted at the time of inquiry.

Are You New to CNC Machining? We’ll Train You!

CNC machining is easier to use than ever before. CNT Motion technicians will provide on-site training at the time of installation, with most customers quickly becoming skilled users.

CNT-950 SERIES SOLID SURFACE MODEL FEATURES

- 1500 IPM Positioning Speeds X- & Y-axes

- 500 IPM Positioning Speeds Z-axis

- AC Brushless Closed-loop Servo

- X- & Z-Axis Hiwin Ball Screw Drive

- Y-Axis Helical Rack-and-pinion Drive

- Z-Axis has 7″ Vertical Motion

- 60″ Wide X 144″ Long Cutting Area*

- 74″ Wide X 171″ Long Machine Foot Print

- Perimeter Cable E-Stop

- Computer Control Spindle On/Off/Speed Changes

- Automatic Tool Length Measure Switch

- 64″ X 171″ Structural Table Base and Long Rails

- Includes Onsrud Tooling Package for Nested Manufacturing

- Pressurized and Lubricated 25mm Bearing System

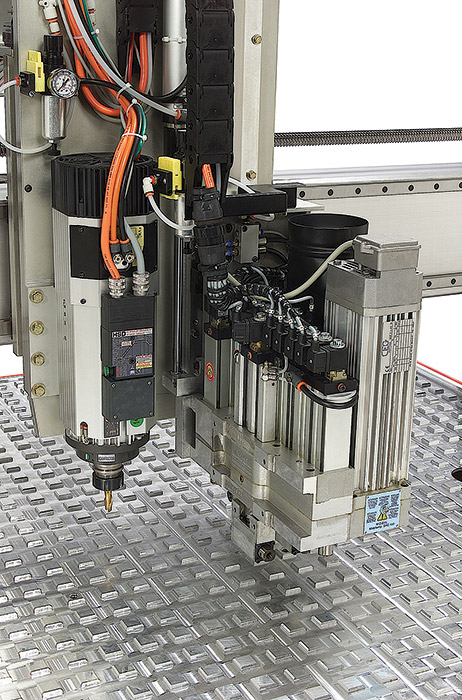

- One 12-HP HSD ISO30 Four-pole 230V Tool Change Router

- Long-nose Spindle with Advanced Dust Collection 24,000 RPM On The Fly Spindle Speed Control

- 12-station Fixed Tool Bar and Eight ISO30 Tool Holders

- 25-HP FPZ Regenerative Vacuum Blower and Switch Gear

- 13.2 Hg, 380 CFM, 60″ X 144″ X 1/2″ Aluminum Vacuum Grid

- Five Air-actuated Pop-up Pin Material Stops

- EnRoute7 Plus CAD/CAM Software with Nesting

- Windows10 Pro Computer with 17” Monitor

- Windows CNC Controller Software

- NEMA 12 Computer Control Cabinet

- 3-day Installation and Training (Does not include Installers’ Travel Expenses, Accommodations and Per Diem.)

*Other sizes available. Call for details.

CNT-950 SERIES SOLID SURFACE MODEL SPECIFICATIONS

Repeatability: .001″

Positioning Accuracy: ±.002″

Cutting Area: 60″ X 144″ *

Z-axis Travel: 7″ or 11″ *

Rapid Traverse: 1500 IPM

Drive Motor: Servo

Y-axis Drive System: Helical Rack-and-pinion

X- & Z-axes Drive System: Hiwin Ball Screw

Controller: Windows 10 PC

Warranty: 1 Year

Weight: Approx. 2800 Lbs.

*Standard specs. Optional dimensions available. Call for details and pricing.

CNT-1000 SERIES 60 MODEL FEATURES

- A full-sized, 60″X144″, all-side-loading machining area

- 2200 IPM Positioning Speeds X- & Y-axes

- 500 IPM Positioning Speeds Z-axis

- AC Brushless Closed-loop Servo

- Y-Axis Helical Rack-and-pinion Drive

- X- Z-Axis Hiwin Ball Screw Drive

- Z-Axis has 11″ Vertical Motion

- 60″ Wide X 144″ Long Cutting Area

- 100″ Wide X 171″ Long Machine Footprint

- Perimeter Cable E-Stop

- Computer Control Spindle On/Off/Speed Changes

- Automatic Tool Length Measure Switch

- 64″ X 171″ Structural Table Base

- Includes Onsrud Tooling Package for Nested Manufacturing

- Pressurized and Lubricated 25mm Bearing System

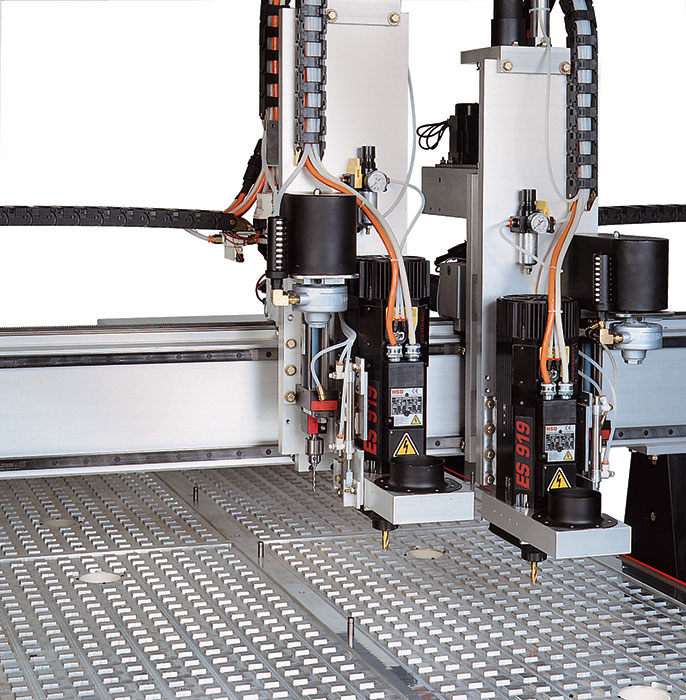

- One 12-HP HSD ISO30 Four-pole 230V Tool Change Router

- Long-nose Spindle with Advanced Dust Collection 24,000 RPM On-the-fly Spindle Speed Control

- Two 2-Station Tool Bar and 8 ISO30 Tool Holders, 4 Tools Mounted on 12-Station Fixed Tool Bar

- HSD Multi-spindle 32mm Boring 5 X and 8 Y Drills (Optional — shown in photo)

- 25-HP FPZ Regenerative Vacuum Blower and Switch Gear

- 13.2 Hg, 380 CFM, 60″ X 144″ X 1/2″ Aluminum Vacuum Grid

- Five Air-actuated Pop-up Pin Material Stops

- EnRoute7 Plus CAD/CAM Software with Nesting

- Windows10 Pro Computer with 17” Monitor

- Windows CNC Controller Software

- NEMA 12 Computer Control Cabinet

- 3-day Installation and Training (Does not include Installers’ Travel Expenses, Accommodations and Per Diem.)

CNT-1000 SERIES 60 MODEL SPECIFICATIONS

Repeatability: .001″

Positioning: Accuracy ±.002″

Cutting Area: 60″X144″ *

Z-axis Travel: 11″ *

Rapid Traverse: 2200 IPM

Drive Motor: Servo

Y-axis Drive System: Helical Rack-and-pinion

X- & Z-axes Drive System: Hiwin Ball Screw

Controller: Windows 10 PC

Warranty: 1 Year

Weight: Approx. 4500 Lbs.

*Standard specs. Optional dimensions available. Call for details and pricing.

Control it from a PC!

Every CNC machine comes with WinCNC Software pre-installed. Ask about our industry-specific custom applications.

FABRICATING SOLID SURFACE?

Expand your capabilities, improve efficiency and reduce material waste.

These CNC machines are ideal for kitchen countertops, bathroom vanities, tub surrounds and more, residential and commercial.