Fixturing Solutions

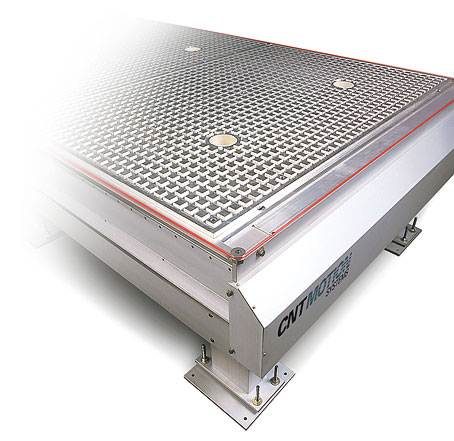

CNT Motion Standard Vacuum System with Blower

CNT Motion’s standard vacuum system features a plenum grid made of aluminum-cast tool and jig plate. Aluminum is the material of choice of all manufacturers of heavy-duty machines due to its greater stability than plastics or composites. Two available blower styles are geared toward specific applications: a 25-HP FPZ regenerative blower; or a 7.5-HP Rietschle Zephyr claw pump.

The machines shown below are examples of fixturing and clamping systems we’ve provided to CNT Motion customers over the years.

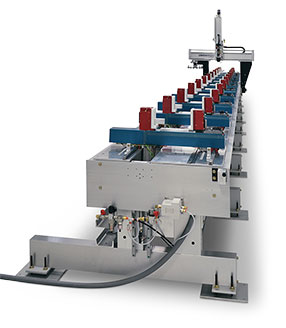

Automated Clamping and Hold-Down Fixtures for Extrusions up to 50 Feet

Designed to drill and mill aluminum extrusions up to 50-foot long for curtain walls. With the extra long bed, pivoting head, automatic tool changer and alcohol/oil coolant system, this CNT machine provides a single-step, automated solution.

LEARN MORE

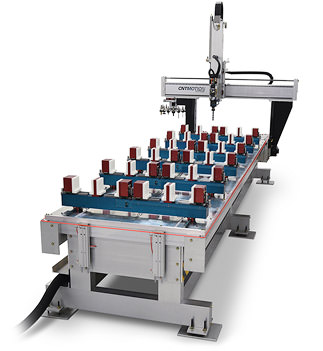

Removable Vise Deck for Fully Functional Vacuum Access

With a 12-foot bed, 24 vise clamp positions, eight pop-up position stops, pivoting head, 16-position automatic tool changer and alcohol coolant system, the CNT machine provides a single-step automated solution designed to drill and mill aluminum extrusions for a variety of applications, including door & window frames, aircraft components, lighting enclosures and wall systems.

LEARN MORE

Air-Activated, Self-Centering Clamps to Hold Fence Posts

Our fence machines feature special air-activated, self-centering clamps to hold PVC, wood or aluminum fence posts ranging from 1-8″ in width. The two-, four- and eight-spindled configurations deliver high production for this efficient, affordable solution.

LEARN MORE

Four 15" X 120" Vacuum Zones with Electric Switch Control

This machine features four 15″ X 120″ work cells with vacuum zones for high-speed manufacturing of snowboards and skis. The company has four of these machines producing hundreds of thousands of products a year. And, during their peak season, they’re running the machines 24/7!

LEARN MORE

Surfboard Support and Hold-Down System

Engineered for high-production surfboard shaping. Incorporating a specialized support system, digitizing capability and industry-standard surfboard shaping software, this machine has enabled our clients to successfully pursue this challenging market using automation to boost both productivity and creativity.

LEARN MORE

Air-Activated Clamping and T-Slot Fixturing

Used for profiling reinforced fiberglass plastic 2″ tall, 4″ wide and up to 35′ in length. Once machined, 2″ ceramic profiles are bonded to the material and (using the same machine) ground to within .002″ tolerance over the entire length and then polished to a #5-8 finish.

LEARN MORE

Pneumatic Lathe Chucks & Cylinders

This machine was the centerpiece of a design that incorporated a CNC extractor feeding a CNC overhead auto-loader/unloader with part orientation and size identification, then feeding this lathe/mill unit, back to unloader and the, finally, to an out-feed conveyor.

LEARN MORE

FIXTURING IS A BIG DEAL

But nothing too challenging for CNT Motion Systems.

Speak to a CNT Motion engineer about your unique materials, and we’ll help you get a fix on holding it in place for efficient and repeatable parts production.