4-Axis CNC Lathe Mill

A Fully Autonomous State-of-the-Art Composite Fabrication Facility

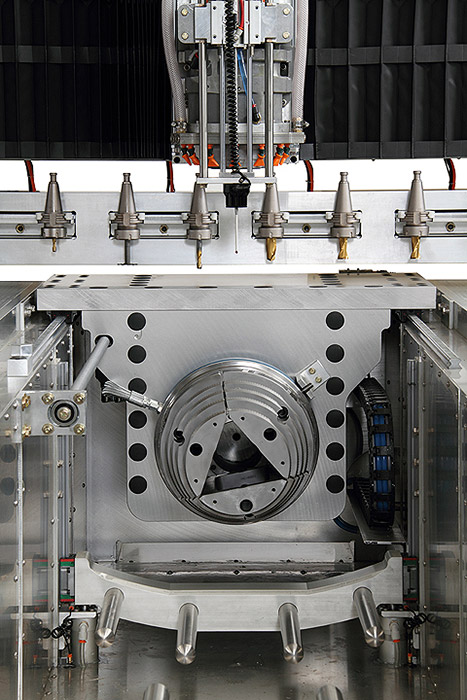

CNT-1100 Series 4-Axis CNC Lathe Mill with Live Tooling

This unique machine design best illustrates CNT Motion’s ability to provide automation solutions to boost throughput and create a fully autonomous state-of-the-art composite fabrication facility. This 4-axis CNC lathe mill machine was the centerpiece of a design that incorporated a CNC extractor feeding a CNC overhead auto-loader/unloader with part orientation and size identification, then feeding this lathe/mill unit, back to unloader and the, finally, to an out-feed conveyor.

*Due to fluctuating supply markets, prices shown are subject to change. Please use pricing shown for reference only. Machines will be quoted at the time of inquiry.

Are You New to CNC Machining? We’ll Train You!

CNC machining is easier to use than ever before. CNT Motion technicians will provide on-site training at the time of installation, with most customers quickly becoming skilled users.

4-AXIS CNC LATHE MILL FEATURES

- 30″ Wide X 168″ Long Cutting Area

- 84″ Wide X 234″ Long Machine Footprint

- Emergency Stop Switch on Computer Cabinet

- AC Brushless Closed-loop Servo Drives

- An IBM-compatible PC, State-of-the-art WinCNC™ Motion Control Software in a NEMA 12 Cabinet

- Computer Control Spindle On/Off/Speed Changes

- Automatic Tool-length Measure Switch for Calibrating End Mills and Drills

- Gravity-feed Drip Pan Base with Wash-down Bars to Move Material into Chip Filtration System

- LNS Turbo Microfine-2 Drum Filter Chip Conveyor

- Blue Control Cabinet with Stack Light Indicator

- Automatic Tool-length Measure Switch

- Cold Gun Cabinet Cooler Units for Electronics

- On/Off Control of Coolant Flood

- Pressurized and Lubricated 25mm Bearings with Large Reservoir for Self-filling Auto Lube Oil System

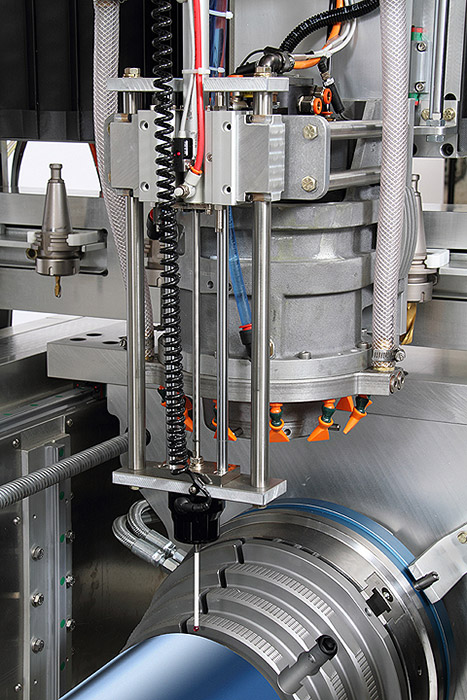

- One 15Kw HSD HSK F63 Four-pole 380V Long-nose Liquid-cooled Tool Change Spindle with Chiller Unit

- Halo with 12 Adjustable Flood Nozzles, Water Flow Sensor and Air Pressure Sensor

- Four Tool Bars on Machine Bridge with Eight ISO40 Tool Holders to Support 5″ Maximum Diameter Tools

- Granite-style Bridge and Gusset Structure with Additional Lead Weight and Cross Support;

- Gortac Heat-sealed Way Cover on Y-axis to Cover Rail and Ball Screw

- Flow Pro, Inc. Model PBLS-6.5 Automatic Filtration System with 20-micron Filtration Media

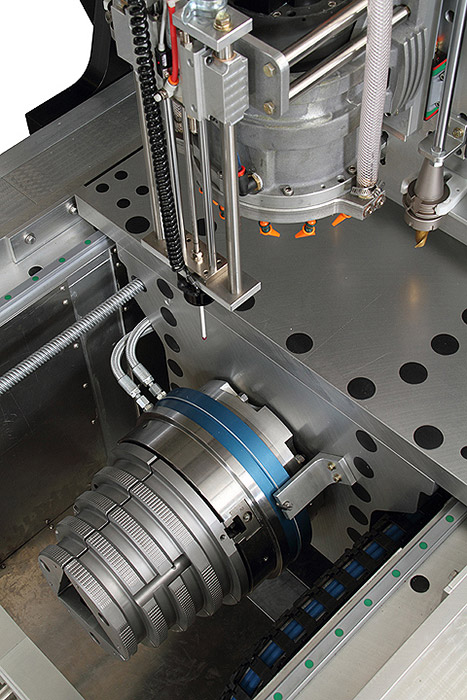

- Two SMW Autoblok SP 350-115 3J Z235 Pneumatic Lathe Chucks & Cylinders Mounted on Nabtesco

- RD-E Series 080E In-line Reduction Gear Boxes and Servo Actuators to Provide Dual-powered Chucking

- Renishaw Touch Probe System Carried on Z-head with Retractable Slide Actuator

- Two Pneumatic Lifting Cradles for Part Orientation During Loading and Unloading

- Two Servo-actuated V-block Center Rests for Part Orientation During Load and Unload Sequence

- Remote Key Pad to Jog Machine and Run Programs

4-AXIS CNC LATHE MILL SPECIFICATIONS

Repeatability: .001″

Positioning Accuracy: ±.002″

Cutting Area: 30″ X 168″

Z-axis Travel: 24″

Rapid Traverse X & Y: 2000 IPM

Rapid Traverse Z: 500 IPM

Lathe Rotational Speed: 70 RPM Maximum

Tailstock: 1000 IPM

Drive Motor: Servo

Y-axis Drive System: Armoloy Coated Helical Rack-and-pinion

X-, Z- & Tailstock Axes Drive System: Armolloy coated Hiwin Ball Screw

Controller: Windows® PC

Warranty: 1 Year

Weight: Approx. 12000 Lbs.

Control it from a PC!

Every CNC machine comes with WinCNC Software pre-installed. Ask about our industry-specific custom applications.

A UNIQUE DESIGN FOR AN AUTOMATED SOLUTION.

This 4-axis CNC lathe mill can become the centerpiece of your shop.

Contact us today to learn more about CNT Motion’s 4-axis CNC technology.