Curtain Wall CNC Fabrication

Curtain Wall CNC Machining for Aluminum Extrusions

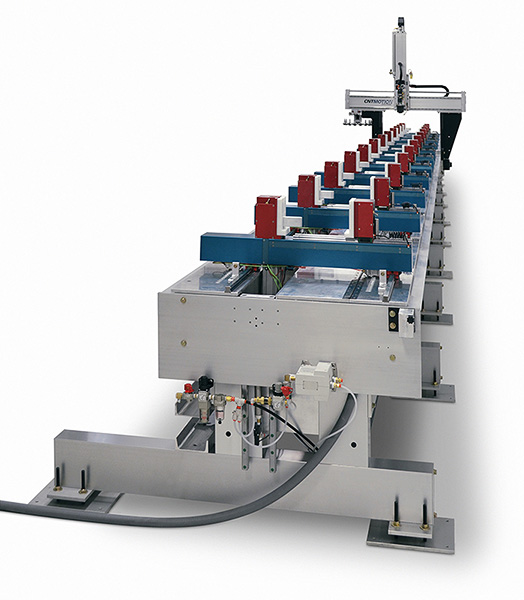

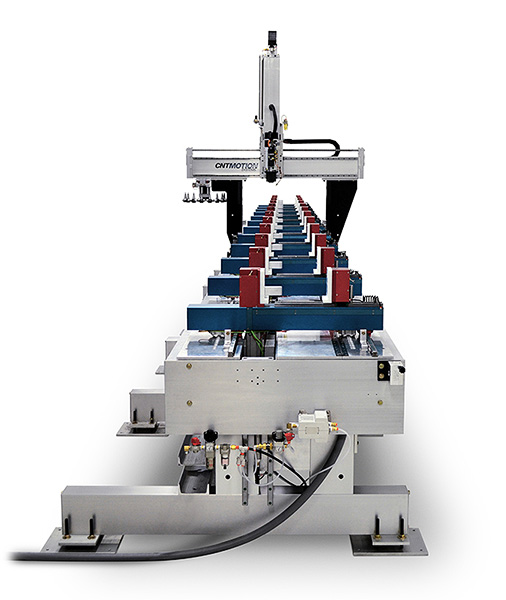

CNT-1000 Series Curtain Wall CNC Fabrication Machine with One Tilting Z-Head and 15″ X 36′ Work Envelope

The only Curtain Wall CNC machine for aluminum extrusions with vertical and horizontal clamp-down fixturing.

In 1999, CNT built the first of several machines designed to drill and mill long aluminum extrusions for pre-engineered commercial building exterior wall coverings, known as curtain walls. (This operation was previously being performed by individuals with drills and tape measures. The milling was done separately on a manual Bridgeport, requiring frequent indexing of the part.) Today, we’re offering a single-step, automated curtain wall CNC fabrication solution with a standard work envelope that’s even larger, a pivoting head, automatic tool changer and alcohol/oil coolant system.

This is also a perfect solution for machining aluminum extrusions for door and window frames.

*Due to fluctuating supply markets, prices shown are subject to change. Please use pricing shown for reference only. Machines will be quoted at the time of inquiry.

Check out the 24-foot, two-panel processing machine we built for the ACM/Alucobond industry.

FEATURES OF MACHINE SHOWN*

- NEMA 12 Control Cabinet with 1000 BTU Cabinet Cooler

- Perimeter Cable E-Stop with I/O for Customer Safety Equipment

- Computer Control Spindle On/Off/Speed Changes

- Automatic Tool Length Measure Switch

- Pressurized and Lubricated 25mm Bearing and Ball Screw System

- C-Axis for Head Rotation ±90 Degrees for Machining Sides of Parts

- One 12HP HSD ISO30 Four-pole 230V Tool Changer

- 15-station Tool Turret and Eight ISO30 Tool Holders

- Drum Thief SMC Alcohol Misting System

- 12 Vises with Auto Place Setting Down Length of Table with Vertical and Horizontal Clamps for Part Holding

- Four Pop-up Part Location Pins

- Four Days of Installation and Training

- Bar Code Reader with G-Code File Association Software

*CNT can manufacture automated clamping and hold-down fixtures, or the customer can provide their own.

SPECIFICATIONS OF MACHINE SHOWN**

Repeatability: 0.001″

Positioning Accuracy: ± 0.002″

Cutting Envelope of Machine: 15″ Wide X 36′ Long**

Work Envelope of Clamps: 1″ to 15″ Wide Clamp Range**

Z-axis Travel and Clearance: 18″ **

Rapid Traverse X & Y: 2000 IPM

Rapid Traverse Z: 500 IPM

Drive Motor: Servo

X-axis Drive: Helical Rack-and-pinion

Y- and Z-axes Drives: Ball Screw

Controller: WinCNC PC-based Controller

Warranty 1: Year

Weight: Approx. 10000 Lbs.

**Standard specs. Optional dimensions available. Call for details and pricing.

LOOKING FOR A SMALLER FOOTPRINT?

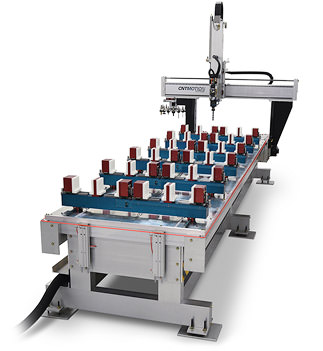

CNT-1000 Extrusion Series CNC Machine with One Tilting Z-head 4′ X 12′ Work Envelope

A single-step automated solution designed to drill and mill aluminum extrusions for a variety of applications, including door & window frames, aircraft components, lighting enclosures and wall systems.

UNIQUE APPLICATION?

Look no further. It’s our specialty.

Just because you don’t see it here, that doesn’t mean we can’t build it. CNT Motion Systems can design a solution that’s just right for your product or application. Let’s talk.