Table Designs

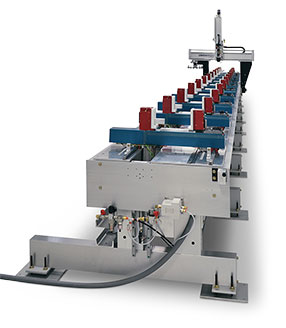

Long Table for Machining Curtain Wall and Extrusions

Designed to drill and mill aluminum extrusions up to 50 feet long for curtain walls. With the extra long bed, pivoting head, automatic tool changer and alcohol/oil coolant system, this CNT machine provides a single-step, automated solution.

LEARN MORE

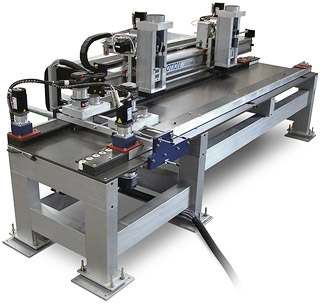

60" X 264" Cutting Area with Two Work Cells

Machine two pairs of stringers up to 20′ long on a 60″ X 264″ cutting area with two 30″ X 264″ work cells. Our standard CNT-1000 Stair Stringer Machine has two individually programmable X-axes for mirror-image and split-head machining to optimize material for the best possible yield.

LEARN MORE

Conveyor Feed-through Parts Machining

This machine was designed to be installed inline with an existing panel processing cutter. The pre-cut parts are pushed into the machine from a stacker where an optical sensor activates the ball screw clamping of the servo-driven, conveyor-style belt feed.

LEARN MORE

Removable Cross Members for 4' Diameter Turning

The industry’s most powerful 4-Axis CNC foam carving and flatbed router delivers capabilities unavailable from traditional processes or lesser machines. This powerful machine’s industrial strength, top-of-the-line features and unequaled precision enable you to expand your product offerings and broaden your market reach. Turn your imagination into reality by creating larger and more intricate pieces than ever before!

LEARN MORE

12' X 4' Front-Loading Table

A renowned manufacturer of inspirational art, home decor and gifts has deployed two of these machines for 3D high-resolution carving of various hardwoods — four to eight pieces at a time. To ease loading/unloading, CNT Motion specially designed a custom 12′ X 4′ front-loading table.

LEARN MORE

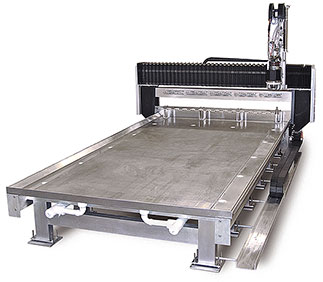

72″ X 168″ Cutting Area

A Virginia-based state-of-the-art facility has deployed two of these powerful CNT stone fabrication CNC machines for high-precision stone countertop and mantle production. This machine holds 30 tools (15 on-the-fly; 15 rack-mounted) and has a 72″ X 168″ cutting area.

LEARN MORE

11' X 20' Work Envelope

This 11′ X 20′ machine has four feet of Z-travel/clearance and a tilting spindle for a California-based company that provides services for many of the leading aerospace companies, offering prototyping and production services that utilize this CNC machining center’s unique size and flexibility.

LEARN MORE

Table Configurations Designed to Your Specific Metalworking Application

CNT Motion has been producing large-work-area metalworking CNC Router/Mills as a cost-effective solution for milling large, light-gauge to medium-thickness steel, aluminum, copper, brass and other metal bar/plate. Table options include, Flat Bed, Drop Bed, Over-and-Under, In-Line Conveyor, or designed to your application.

LEARN MORE

48" Wide X 420" Long Cutting Area

Used for profiling reinforced fiberglass plastic 2″ tall, 4″ wide and up to 35′ in length. Once machined, 2″ ceramic profiles are bonded to the material and (using the same machine) ground to within .002″ tolerance over the entire length and then polished to a #5-8 finish.

LEARN MORE

30" X 168" Lathe with Live Tooling

This machine was the centerpiece of a design that incorporated a CNC extractor feeding a CNC overhead auto-loader/unloader with part orientation and size identification, then feeding this lathe/mill unit, back to unloader and the, finally, to an out-feed conveyor.

LEARN MORE

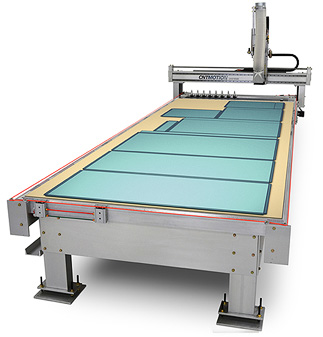

5' X 24' Work Envelope for Aluminum Composite Panels (Alucobond)

Large enough to handle two panels of Alucobond at a time and accurate enough to V-groove to within +0.002″ depth over a 5′ X 24′ surface area. Also available in our CNT-950 Series configuration.

LEARN MORE

LIKE WHAT YOU SEE?

Let’s see if we can get you a table configuration that’s just right.

Contact CNT Motion Systems and speak to an engineer.