CNC Stair Stringer & Tread Machine

A CNC Solution Built in Response to Growing Demand.

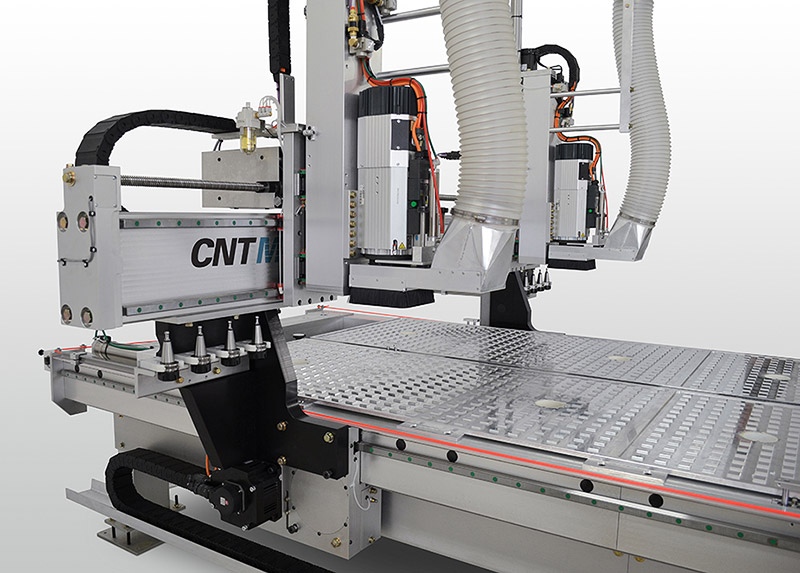

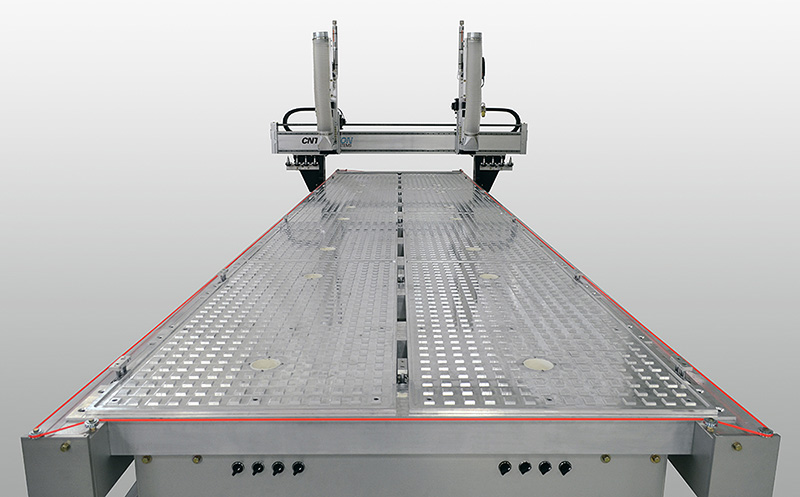

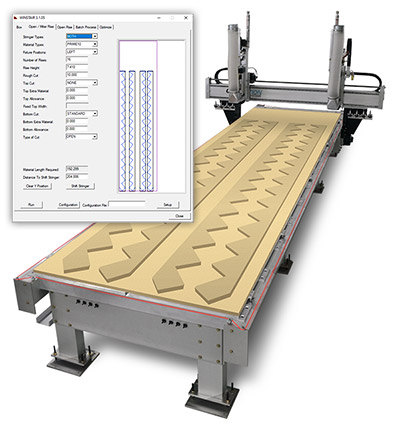

CNT-1000 Dual-Head CNC Stair Stringer and Tread Machine

Since 1992, CNT Motion has been building machines for cutting stair stringers and treads. Our standard CNT-1000 Stair Stringer Machine has two individually programmable X-axes, each attached to a Z-head for mirror-image and split-head machining to optimize material for the best possible yield. A custom software program allows you to pick material type and thickness, rise and run, style of stringer (box, open, horse cut, winder, etc.) and end cuts. Also available in our CNT-950 configuration.

The CNC Stair Stringer and Tread solution is also availble in our popular CNT-950 configuration. See specifications below for both the CNT-1000 and CNT-950 models.

*Due to fluctuating supply markets, prices shown are subject to change. Please use pricing shown for reference only. Machines will be quoted at the time of inquiry.

WinStair, Stringer Gcode Generator

Apply your specifications and generate Stair Stringer G-Code in seconds. WinStair supports tool changers and stored confgurations to meet the users specifications. This software can be setup to use a machine with a single router, or for a machine with dual routers for faster production. Different types of stair stringers can be setup parametrically and again the GCode is sent directly to WinCNC. There is also a batch option where a spreadsheet of stringers can be loaded automatically and then the user can select the groups of stringer to cut. A materials list is also imported and the stringers are grouped to reduce material waste. This software also has an add-on that automatically prints custom labels on a label printer.

Ask about our 16-foot hand rail boring machine, featuring an adjustable-angle head, air-activated clamping system (for plates and rails) and servo control.

CNC Stair Stringer and Tread Machine Videos

CNT-1000 Dual-Head Stair Stringer and Tread Machine Features & Specifications

CNT-1000 STAIR STRINGER AND TREAD MACHINE FEATURES

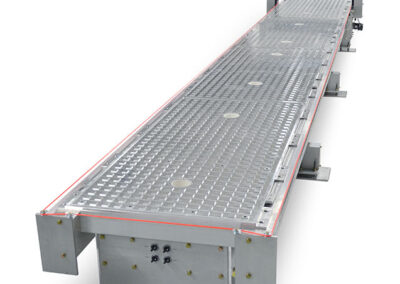

- 60″ Wide X 264″ Long Cutting Area with Two 30″ Wide X 264″ Long Work Cells

- Eight 30″ X 66″ (Four Left and Four Right) Vacuum Zones with Electric Switch Control On/Off

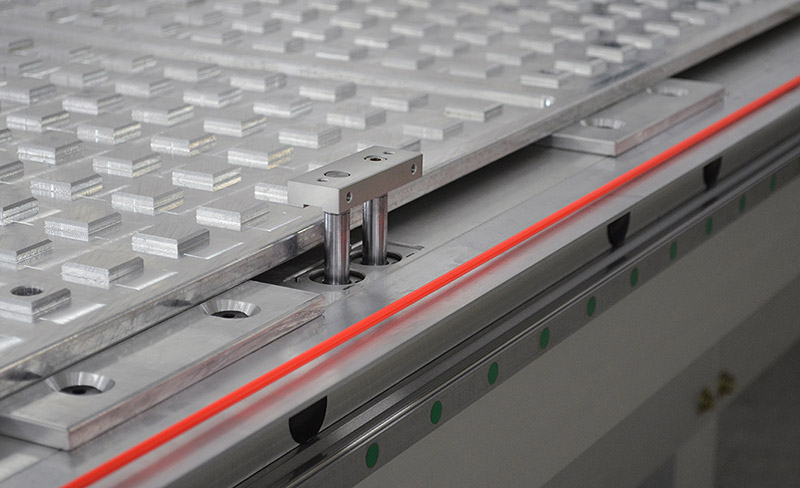

- Pin Stops along Length of Outside Cutting Area for Material Reference;

- 96″ Wide X 288″ Long Machine Footprint

- AC Brushless Closed-loop Servo Drives

- An IBM-Compatible PC, State-of-the-art WinCNC™ Motion Control Software in a NEMA 12 Cabinet

- A Full-perimeter Cable E-Stop

- Computer Control Spindle On/Off/Speed ChangesAutomatic Tool-length Measure Switch

- Onsrud Tooling Package for Stair Stringers

- Pressurized and Lubricated 25mm Bearing System

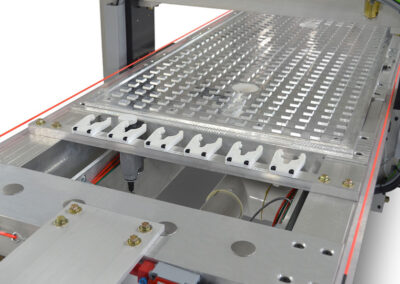

- Two 10hp HSD ISO30 Four-pole Long-nose 230V Tool Changers with Advanced Dust Collection

- Four Two-station Tool Bars and Eight ISO30 Tool Holders

- Two 25hp Two-stage Regenerative Vacuums and Grid Hold-down

- Microsystems Stringer G-Code Software

CNT-1000 STAIR STRINGER AND TREAD MACHINE SPECIFICATIONS*

Repeatability: .001″

Positioning Accuracy: ±.002″

Cutting Area: 60″ X 240″

Z-axis Travel: 11″ *

Rapid Traverse X & Y: 2200 IPM

Rapid Traverse Z: 500 IPM

Drive Motor: Servo

Y-axis Drive System: Helical Rack-and-pinion

X- & Z-axes Drive System: Hiwin Ball Screw

Controller: Windows® PC

Warranty: 1 Year

Weight: Approx. 7000 Lbs.

*Standard specs. Optional dimensions available. Call for details and pricing.

CNT-950 Dual-Head Stair Stringer and Tread Machine Features & Specifications

CNT-950 STAIR STRINGER AND TREAD MACHINE FEATURES

- 60″ Wide X 264″ Long Cutting Area with Two 30″ Wide X 264″ Long Work Cells

- Eight 30″ X 66″ (Four Left and Four Right) Vacuum Zones with Electric Switch Control On/Off

- Pin Stops along Length of Outside Cutting Area for Material Reference

- 80″ Wide X 288″ Long Machine Footprint

- AC Brushless Closed-loop Servo Drives

- An IBM-Compatible PC, State-of-the-art WinCNC™ Motion Control Software in a NEMA 12 Cabinet

- A Full-perimeter Cable E-Stop

- Computer Control Spindle On/Off/Speed Changes

- Automatic Tool-length Measure Switch

- Onsrud Tooling Package for Stair Stringers

- Pressurized and Lubricated 25mm Bearing System

- Two 10hp HSD ISO30 Four-pole Long-nose 230V Tool Changers with Advanced Dust Collection

- Eight-station Tool Bar and Eight ISO30 Tool Holders at Rear of Table

- Two 25hp Two-stage Regenerative Vacuums and Grid Hold-down

- Microsystems Stringer G-Code Software

CNT-950 STAIR STRINGER AND TREAD MACHINE SPECIFICATIONS*

Repeatability: .001″

Positioning Accuracy: ±.002″

Cutting Area: 60″ X 240″

Z-axis Travel: 7″ *

Rapid Traverse X & Y: 1500 IPM

Rapid Traverse Z: 300 IPM

Drive Motor: Servo

Y-axis Drive System: Helical Rack-and-pinion

X- & Z-axes Drive System: Hiwin Ball Screw

Controller: Windows® PC

Warranty: 1 Year

Weight: Approx. 5000 Lbs.

*Standard specs. Optional dimensions available. Call for details and pricing.

CNT-950 30″ Single-Head Stair Stringer and Tread Machine Features & Specifications

CNT-950 30" STAIR SINGLE-HEAD STRINGER AND TREAD MACHINE FEATURES

- 30″ Wide X 240″ Long Cutting Area with one 30″ Wide X 240″ Long Work Cell

- Four 30″ X 66″ (Two Left and Two Right) Vacuum Zones with Electric Switch Control On/Off

- Pin Stops along Length of Outside Cutting Area for Material Reference

- 50″ Wide X 267″ Long Machine Footprint

- AC Brushless Closed-loop Servo Drives

- An IBM-Compatible PC, State-of-the-art WinCNC™ Motion Control Software in a NEMA 12 Cabinet

- A Full-perimeter Cable E-Stop

- Computer Control Spindle On/Off/Speed Changes

- Automatic Tool-length Measure Switch

- Onsrud Tooling Package for Stair Stringers

- Pressurized and Lubricated 25mm Bearing System

- One 12hp HSD ISO30 Four-pole Long-nose 230V Tool Changer with Advanced Dust

- Collection

- Six-station Tool Bar and Eight ISO30 Tool Holders at Rear of Table

- One 25hp Two-stage Regenerative Vacuums and Grid Hold-down

- Microsystems Stringer G-Code Software

CNT-950 30" SINGLE-HEADE STAIR STRINGER AND TREAD MACHINE SPECIFICATIONS*

Repeatability: .001″

Positioning Accuracy: ±.002″

Cutting Area: 30″ X 240″

Z-axis Travel: 7″ *

Rapid Traverse X & Y: 1500 IPM

Rapid Traverse Z: 300 IPM

Drive Motor: Servo

Y-axis Drive System: Helical Rack-and-pinion

X- & Z-axes Drive System: Hiwin Ball Screw

Controller: Windows® PC

Warranty: 1 Year

Weight: Approx. 4000 Lbs.

*Standard specs. Optional dimensions available. Call for details and pricing.

IS THIS THE YEAR?

Take the next step toward getting a new CNC Stair Stringer and Tread machine.

Contact a CNT Motion engineer today to learn more. We’ll help you determine which solution is best for your busienss.