Curtain Wall CNC with Kurt Vises

Curtain Wall CNC Machine with Tilting Head, 14 Kurt Vises and 33″ X 510″ Cutting Area

CNT-1000 Series Curtain Wall Machine with C-Axis Tilting Head, 14 Kurt Vises and 33″ X 510″ Cutting Area

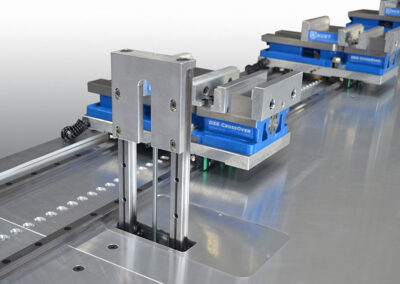

Featuring 14 Kurt DX6 Vises mounted on 25mm linear guideways to allow adjustable support and movement along the length of the machine.

This 33″ X 42′ cutting area, 4-Axis, 1000 Series CNC was originally built to machine heavy wall aluminum parts for trailers and truck bodies. It has 14 Kurt DX6 Vises mounted on 25mm linear guideways to allow adjustable support and movement along the length of the machine. Air clamps hold the vises in place, once moved to your desired position and activated by a switch conveniently located below the vise screw handle engagement.

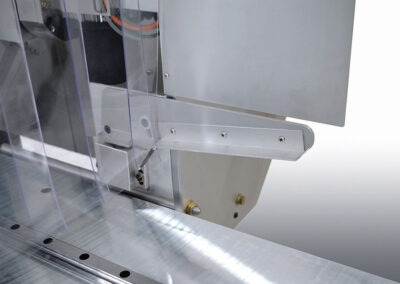

Four pop-up-stops allow for:

- Four (4) 132″ and one (1) 96″ part to be clamped at one time

- One (1) 268″ and one (1) 240″ part to be clamped at one time

- One (1) part 510″ long

An enclosure with windows allows the operator to observe the machining operation while remaining protected. Four pause buttons are symmetrically positioned on both sides of the enclosure, with two facing forward and two facing rearward. They allow the operator to pause or restart the machine while it is in operation. Overall, this CNC machine offers a robust and versatile solution for machining long, heavy-wall aluminum parts.

*Due to fluctuating supply markets, prices shown are subject to change. Please use pricing shown for reference only. Machines will be quoted at the time of inquiry.

Check Out All of Our CNC Curtain Wall Machines

FEATURES OF MACHINE SHOWN

- Starter Set of Router Bits ($700.00 Value) Includes End Mills for Wood/Plastic/Metal, Depending on Your Application.

- Type 12 UL-Listed Enclosure on Casters that Houses all Electronics, Windows11 Pro Computer with 17″ Flat Screen Color Monitor, 16 GB of RAM, 6 USB Ports, Wireless Keyboard and Mouse.

- One 12-HP (9kW) HSD ISO30 4-Pole 230V Tool Change Long Nose Spindle; 24,000 RPM On-the-fly Spindle Speed Control; SMC Drum Thief for Alcohol/Coolant Misting System; and Spindle-Mounted Spray Delivery Nozzle.

- 15 Total Tool Positions are Available on the Bridge Turret. The Machine Comes with 8 ISO 30 Tool Cones and Your Choice of 8 Collets for the Diameter of the Tools You Choose. Additional Tool Cones and Collets can be Purchased.

- 4 Days Installation and Training. Purchaser is Responsible for All Travel and Lodging Expenses of Installation/Training Personnel, including Excessive Travel.

SPECIFICATIONS OF MACHINE SHOWN

2200 IPM Positioning Speeds X- & Y-Axes

500 IPM Positioning Speed Z-Axis

Mitsubishi AC Brushless Closed-Loop Servos

Y-Axis Helical Rack-and-Pinion Drive

X-Axis 25mm Hiwin Rotating Nut Ball Screw Drive

Z-Axis 16mm Hiwin Ball Screw Drive

C-Axis 161:1 Nabtesco Cycloidal Gear Reducer

C-Axis Head Rotation -92 Degrees/+92 Degrees

33″ wide X 510″ long X 20″ tall, Cutting Area, 25″ Throat

Travel 60″ X-Axis, 527″ Y-Axis, 24″ Z-Axis

62″ wide X 527″ Long Structural Table Base

93″ wide X 565″ long X 122″ tall, Physical Footprint

Computer Control Spindle On/Off/Speed Changes

Automatic Tool Length Measure Switch

15-Position Tool Turret on Retractable Slide

Includes Onsrud Tooling Package (See Below)

Pressurized and Lubricated 25mm Bearing System

4 Air-Actuated Pop-Up Stops for Locating Material

Two Vise Handle Emergency Stop Arms located + Y-Axis

WinCNC Windows Controller Software

NEEDED TO OPERATE THIS MACHINE

- 208/230V three-phase power (60 Amp Service)

- An isolated ground rod will need to be driven into the ground to connect the #12 ground wire from the computer control cabinet. This ground rod must not be a shared ground, building ground, water pipe ground, or any other ground. Your electrician will need to run the 60 Amp 208/230V three-phase service line to the disconnect located on the side of the control cabinet enclosure.

- Provide 5-9 CFM at 95-105 PSI, refrigerated clean, dry air to the machine.

Control it from a PC!

Every CNC machine comes with WinCNC Software pre-installed. Ask about our industry-specific custom applications.

LOOKING FOR A GREAT CURTAIN WALL MACHINE OPTION?

This robust and versatile solution is great for machining long, heavy-wall aluminum parts.

Let’s talk about your curtain wall CNC machine.