Head Configurations

C-axis for ±95 Degrees of Head Rotation with On-board Probe for Part Deviation Measurement

Designed to drill and mill 30-foot long aluminum extrusions for curtain walls. With the 30-foot bed, pivoting head, automatic tool changer and alcohol/oil coolant system, the CNT machine provided a single-step, automated solution.

LEARN MORE

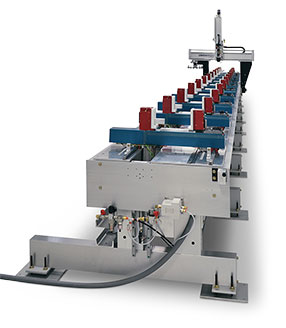

Tilting Z-head Assembly for Extrusions and Small Parts Machining

With a 12-foot bed, 24 vise clamp positions, eight pop-up position stops, pivoting head, 16-position automatic tool changer and alcohol coolant system, the CNT machine provides a single-step automated solution designed to drill and mill aluminum extrusions for a variety of applications, including door & window frames, aircraft components, lighting enclosures and wall systems.

LEARN MORE

Multiple C-Axis Options for Metalworking

Options include Tilt Spindle Head up to 120°; Tooling Rotation 360° plus unlimited; Turntable on Platform Bed, horizontal, rotation 360° plus unlimited, diameter up to 120″; and Lathe-style Rotation 360° plus unlimited, length limited by material up to 500″ long, 36″ diameter.

LEARN MORE

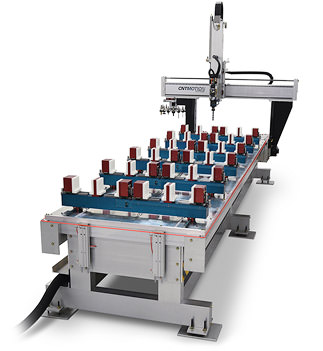

Up to Eight Router Spindles and Eight Aisles for Fence Manufacturing

Our fence machines feature special air-activated, self-centering clamps to hold PVC, wood or aluminum fence posts ranging from 1-8″ in width. The two-, four- and eight-spindled configurations deliver high production for this efficient, affordable solution.

LEARN MORE

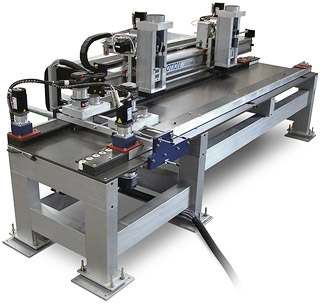

7 Routers for Feed-through Parts Machining

This machine was designed to be installed inline with an existing panel processing cutter. The pre-cut parts are pushed into the machine from a stacker where an optical sensor activates the ball screw clamping of the servo-driven, conveyor-style belt feed.

LEARN MORE

Four Heads Cutting Simultaneously

This machine features four 15″ X 120″ work cells with vacuum zones for high-speed manufacturing of snowboards and skis. The company has four of these machines producing hundreds of thousands of products a year. And, during their peak season, they’re running the machines 24/7!

LEARN MORE

Part Rotation for Live Tooling Lathe Mill

The industry’s most powerful 4-Axis CNC foam carving and flatbed router delivers capabilities unavailable from traditional processes or lesser machines. Top-of-the-line features and unequaled precision enable you to expand your product offerings.

LEARN MORE

Four-Headed High-Resolution Carving Machine

A renowned manufacturer of inspirational art, home decor and gifts has deployed two identical four-headed machines for 3D, high-resolution (4000 steps per inch/.0002) carving of various hardwoods — four to eight pieces at a time.

LEARN MORE

Rotating 4-foot Head for 3D Carving, Prototyping & Modeling

This 11′ X 20′ machine has four feet of Z-travel/clearance and a tilting spindle for a California-based company that provides services for many of the leading aerospace companies, offering prototyping and production services that utilize this CNC machining center’s unique size and flexibility.

LEARN MORE

Rotating Z-Head for Profiling, Grooving and Polishing

Used for profiling reinforced fiberglass plastic 2″ tall, 4″ wide and up to 35′ in length. Once machined, 2″ ceramic profiles are bonded to the material and (using the same machine) ground to within .002″ tolerance over the entire length and then polished to a #5-8 finish.

LEARN MORE

Four-Axis Lathe Mill with Touch Probe System

This machine was the centerpiece of a design that incorporated a CNC extractor feeding a CNC overhead auto-loader/unloader with part orientation and size identification, then feeding this lathe/mill unit, back to unloader and the, finally, to an out-feed conveyor.

LEARN MORE

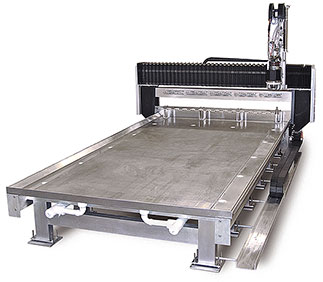

Liquid-Cooled Spindle Assembly for Granite and Stone Profiling, Grinding and Polishing

Designed for high-precision stone countertop and mantle fabrication. The heads features a 12Kw HSD ISO40 Four-pole 380V Long Nose Liquid-cooled Granite Spindle with Inox Coating and Water Jacket, Max 12000 RPM with Halo and 12 Adjustable Flood Nozzles and Water Flow Sensor.

LEARN MORE

GETTING OVERWHELMED?

It’s easy. We have so many machines. And there are others not on this website.

Contact CNT Motion Systems so we can learn about what you’re looking for in a head configuration and how we can help you.