Surfboard Shaping Systems

Using CNC Automation to Boost both Productivity and Creativity

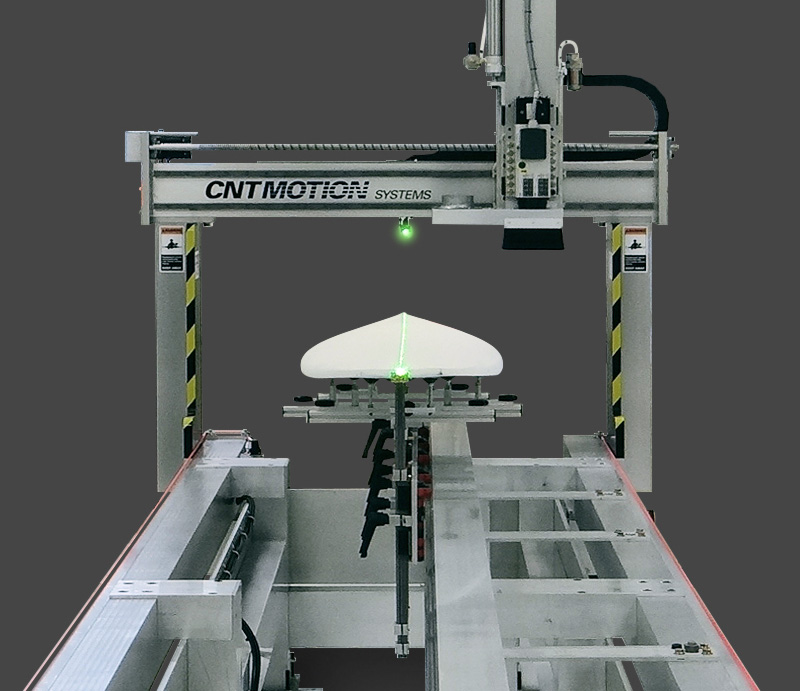

CNT-950 Surfboard Shaping Machine

Since 2000, CNT has been building machines for high-production surfboard shaping. Incorporating a specialized support system, digitizing capability and industry-standard surfboard shaping software, this machine has enabled our clients to successfully pursue this challenging market using automation to boost both productivity and creativity.

Are You New to CNC Machining? We’ll Train You!

CNC machining is easier to use than ever before. CNT Motion technicians will provide on-site training at the time of installation, with most customers quickly becoming skilled users.

CNT-950 SURFBOARD SHAPING MACHINE FEATURES

- 30″ Wide X 174″ Long Cutting Area

- 60″ Wide X 198″ Long Machine Footprint

- AC Brushless Closed-loop Servo Drives

- An IBM-compatible PC, State-of-the-art WinCNC™ Motion Control Software in a NEMA 12 Cabinet

- A Full-Perimeter Cable E-Stop

- Computer Control Spindle On/Off/Speed Changes

- Automatic Tool-length Measure Switch

- Pressurized and Lubricated 25mm Bearing System

- One 9.3hp HSD ER-32 Two-pole 230V Ceramic Bearings and Electric Fan

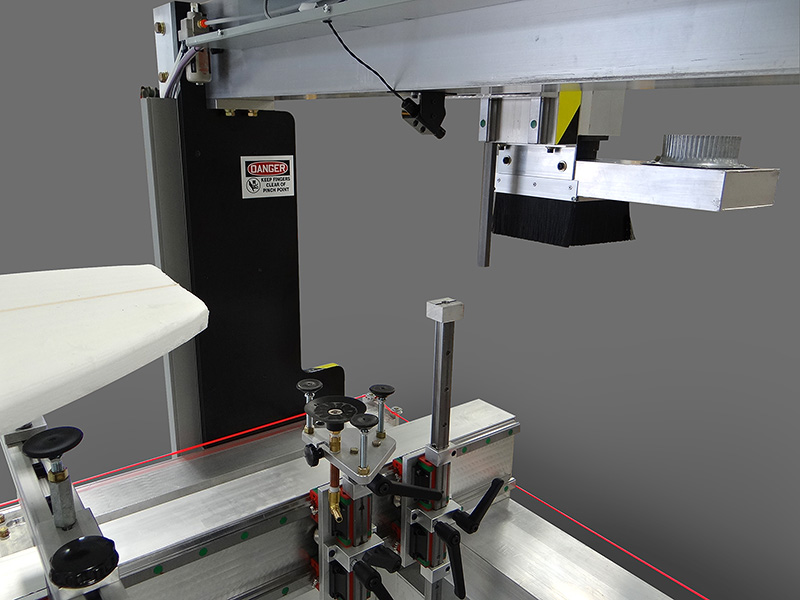

- Dust Collection Hood with 6” Dust Collection Ring

- Surfboard Support and Hold-Down System with 1.5hp 27”Hg Max Vacuum Pump

- Shape 3D Software

- Onboard Probe for Digitizing (available option)

CNT-950 SURFBOARD SHAPING MACHINE SPECIFICATIONS

Repeatability: .001″

Positioning Accuracy: ±.002″

Cutting Area: 30″ X 174″

Z-axis Travel: 16″ *

Rapid Traverse X & Y: 2000 IPM

Rapid Traverse Z: 300 IPM

Drive Motor: Servo

Y-axis Drive System: Armoloy Coated Helical Rack-and-pinion

X- & Z-axes Drive System: Hiwin Ball Screw

Controller: Windows® PC

Warranty: 1 Year

Weight: Approx. 3500 Lbs.

*Standard specs. Optional dimensions available. Call for details and pricing.

Control it from a PC!

Every CNC machine comes with WinCNC Software pre-installed. Ask about our industry-specific custom applications.

RIDE THE CNC AUTOMATION WAVE!

Specifcially designed for this exciting and challenging market.

Contact one of our engineers today to see how we can suit you up with CNC technology.